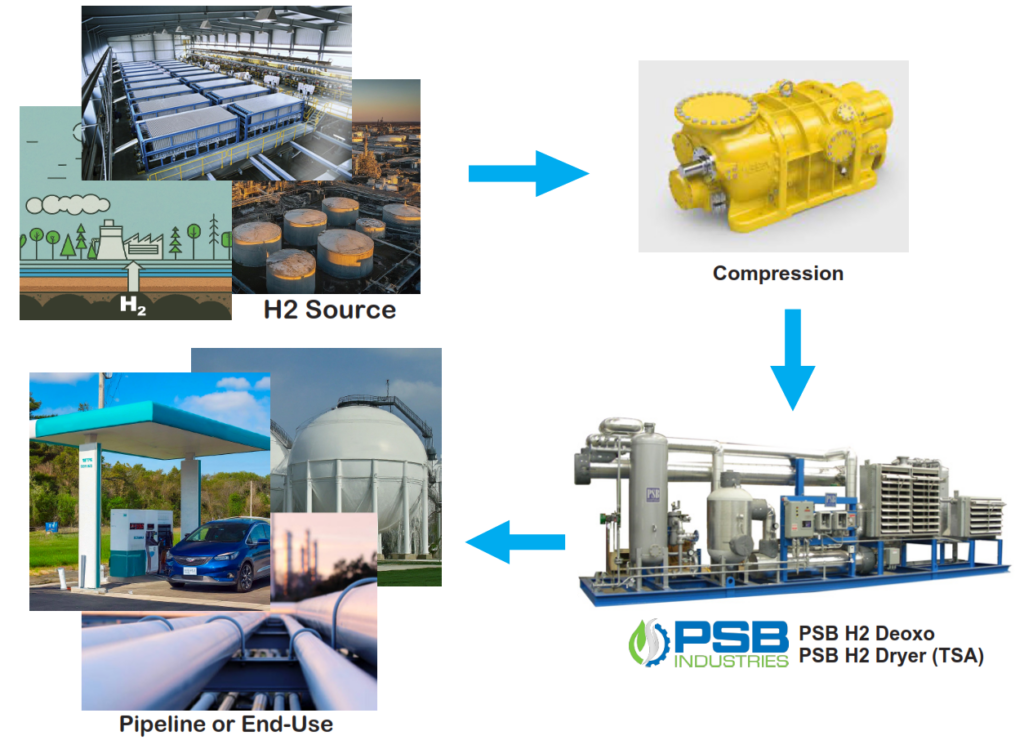

Hydrogen Purification and Drying

Green Hydrogen is produced by splitting water using electricity using renewable sources of energy. H2 leaving the skid is usually saturated with water and may contain trace amount of oxygen depending on the type of electrolyzer used. Depending on the end use, outlet specifications for oxygen and water can be as low as 1 ppmv.

PSB supplied Deox-H2 + TSA combination serves as an ideal solution to treat and purify Hydrogen gas to meet strict outlet specifications. It can handle inlet oxygen concentrations up to 2% and water levels up to saturation limits. The Deox-H2 + TSA is a uniquely designed packaged skid equipped with the necessary subcomponents, instrumentation and controls to ensure continuous operation with minimal operator intervention. PSB supplied media ensures complete conversion of oxygen down to < 1 ppmv and Temperature Swing Adsorption based dryers have the capability of removing moisture from the gas down to < 1 ppmv. Depending on the outlet water specification, PSB offers multiple regeneration strategies to ensure zero gas emission/ loss. A unique multi-layered adsorbent bed ensures that the pipeline specifications are met with ease with relatively low operating expenses thereby optimizing the overall cost of the unit.

Typical pressures range from 200 psig to 580 psig and temperatures from 50 F to 115 F. Values outside of this range can be handled as well. PSB also offers a stand-alone Dryer package if needed for applications not requiring oxygen removal.

PSB Industries

1202 W 12th St. Erie, PA 16501

PSB Industries

1202 W 12th St. Erie, PA 16501