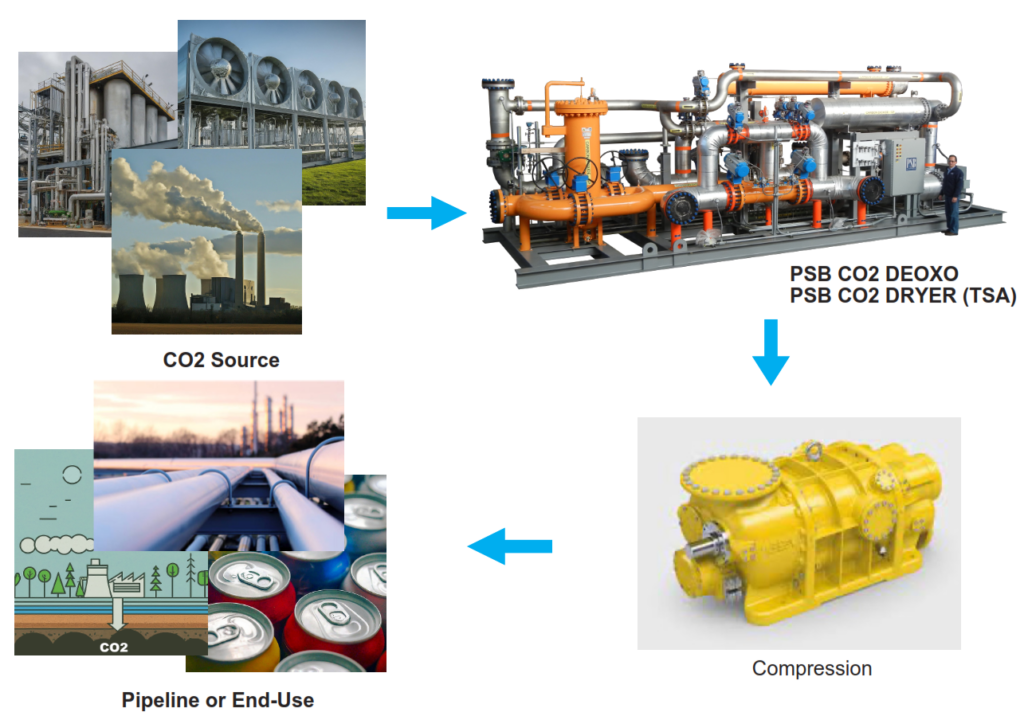

Carbon Dioxide Purification and Drying

Carbon Dioxide is a major source of pollution and contributes to climate change. Amongst the various sources, coal fired plants, steel and cement industries emit the highest amounts of CO2 into the atmosphere. CO2 from these sources is captured and separated from flue gas or off gas via various technologies followed by compression. Clean and compressed CO2 is saturated with water which needs removal prior to pipeline injection.

PSB supplied Temperature Swing Adsorption based CO2 dryers have the capability of removing moisture from the gas from saturated levels down to < 1 ppmv. Depending on the outlet water specification, PSB offers multiple regeneration strategies to ensure zero gas emission/ loss. A unique multi-layered adsorbent bed ensures that the pipeline specifications are met with ease with relatively low operating expenses thereby optimizing the overall cost of the unit.

PSB CO2 dryer package can include upstream coolers and separators to pre-cool the gas. Typical dryer inlet conditions range from 200 psig to 700 psig and from 50 F to 115 F. Values outside of this range can be handled as well.

For Direct Air Capture projects, there is oxygen present in the CO2 gas stream which, depending on the pipeline specifications/ end user, may need removal. PSB supplied Deox-CO2 package can remove oxygen from the gas via hydrogen or natural gas injection down to < 1 ppmv. If oxygen and moisture removal is needed, PSB supplied Deox- CO2 and Dryer package can be a cost effective solution for removal of oxygen and moisture.

PSB Industries

1202 W 12th St. Erie, PA 16501

PSB Industries

1202 W 12th St. Erie, PA 16501